ABSA/Annual Maintenance

If you have an ABSA registered vessel, Climatec Solutions can arrange with ABSA to schedule the inspection of your equipment. We work with ABSA on a regular basis and know what they require and how they like the equipment to look. We can prepare the equipment in a timely manner and have it opened up, inspected and back together as needed.

Climatec Solutions can work with you to create a maintenance schedule that best suites your equipment in order to keep it running at peak performance.

Complete Boiler Service

From top to bottom Climatec Solutions can provide you with knowledgeable, quality work. Boiler services can include combustion analysis, safety checks, cleaning of fire and water sides, welding and tube repairs/replacements and more.

Combustion analysis is a great way to see how efficiently your boiler is running and what can be changed to correct any concerns. Simple trip tests can ensure that all your safety devices are working correctly, and failing when appropriate. Consistent cleaning of fire and water side can result in replacing parts before they are no longer viable, causing down time in your equipment, it can also help your equipment run a longer, more efficient life.

Consistently working with boilers gives us the advantage of knowing what is normal wear and tear and what could be cause for concerns, letting us advise on what requires replacement and what is considered normal for boilers.

Consultations

If you are concerned your heating system is not working to its full potential, feel as though you are not getting the performance from your system and you would like input regarding the condition or design of your system, please contact us.

Climatec Solutions can discuss various options that will improve your current system or discuss upgrading to help reach your heating goals.

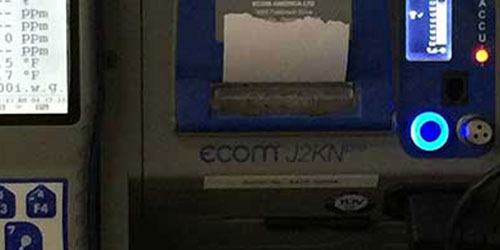

Combustion

Combustion analysis documents several different values to evaluate how efficiently your burner is running. If recorded, a complete document is provided with the results for your records. These reports provide valuable information regarding the performance and efficiency, it also includes the combustion process through each stage of your modulating burner.

This analysis takes into account barometric pressure, air temperature, and pressure in the room to ensure that the burner is set up in real operating conditions. All of these variables can affect the performance of the burner and annual combustion can account for any changes and confirm that the burner flame is at the highest efficiency.

Burner Upgrades

Upgrading your burner can reduce your environmental impact by running lower O2, meeting low NOx requirements and keeping CO production to a minimum. With the install of a proper burner for your boiler, you can ensure that you are burning fuel efficiently as possible. Climatec can ensure the new burner is installed correctly, flame length and diameter does not impose on your pressure vessel, and that controls & combustion are set correctly. This will help provide the longest possible run time and reducing unnecessary cycling, it can also ensure maximum efficiency of the heat exchanger.

Control Upgrades

Climatec Solutions offers various options for upgrading the controls. Upgrading controls can offer communication between the boiler and BMS. We also offer custom control packages with burner and boiler controls built in. Upgrading to a touch screen can combine information, control and operations all to one convenient location.

Parts Replacement

Climatec Solutions can source and install any available boiler parts.

Refractory Repair

Whether the job is a small repair job, re-bricking a firebox or pouring rear doors, Climatec Solutions has the expertise to have your equipment protected by the proper refractory materials.